Optical Coherence Tomography

Optical coherence tomography (OCT) makes it possible to carry out non destructive cross sectional analysis.

MotivationNon destructive measurement and imaging techniques, which can resolve the inner structure of materials play an important role in industrial research and quality control, e.g. for composite materials, plastics, etc. Common measurement approaches like ultrasound techniques only provide a depth resolution of around 100 µm and have the disadvantage that the sample has to be in direct contact with the probing apparatus (e.g. via water or contact gels).

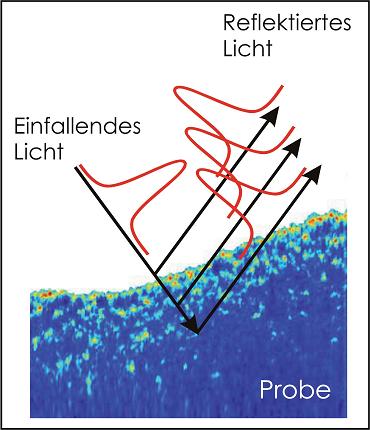

Working PrincipleOptical coherence tomography (OCT) gives the possibility to acquire cross sectional images of the sample under investigation in a contactless and non destructive manner. The depth resolution with this technique generally lies in the range of 3-4 µm and can be improved towards resolutions of as low as 1 µm. The physical phenomenon behind OCT is the interferometric superposition of a reference light wave with light back-reflected from different layers within the sample. The intensity and the travelling times of the back-reflected light waves contain depth resolved information and through the use of mathematical algorithms it is possible to reconstruct cross sectional images of the sample.

|

|

Field of Application

- Non destructive testing of materials

- Analysis tool in process development (e.g. injection moulding processes, extrusion of multi-layered foils)

- Industrial inspection and quality control in the production process (e.g. layer thickness measurements in multi-layered foils).

Nutzen

Im Bereich der Materialwissenschaften gibt es folgende Einsatzgebiete der optischen Kohärenztomographie OCT:

- Zerstörungsfreie Material- und Werkstoffprüfung

- Analysetool in der Prozessentwicklung (z.B. Kunststoffspritzguss, Folienextrusion)

- Industrielle Inspektion und Qualitätskontrolle in der Produktion (z.B. Schichtdickenmessung von Multischichtfolien) – siehe dazu Referenzprojekt.

Anwendungsbereiche

OCT eignet sich speziell für teiltransparente Materialien, wie z.B.

- Kunststoffe (Spritzgußteile, Mehrschichtfolien,…)

- Verbundmaterialien (glasfaserverstärkte Epoxidharzkomponenten,…)

- Metalle (Oberflächenprofile, Beschichtungen)

- Gläser, Keramiken

- Halbleiter