Project 2.2

3D-microstructure and thermo-mechanical investigations of structural metals

The objectives of this project are to correlate 3D microstructural constitution and damage in selected cast AlSi piston alloys and continuously cast steel slabs with the effect of thermo-mechanical loads and...

...following the results obtained in 1), to assess the parameters that lead to damage formation/propagation in terms of alloy composition and processing conditions to improve the performance of the cast products for further processing and in-service behaviour.

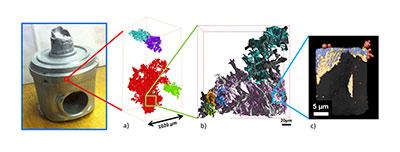

Figure: Multiscale X-ray tomography of cast AlSi piston alloys: a) large 3D structures of aluminides revealed by laboratory cone-beam X-ray tomography – voxel size = (3 µm)³. b) Smaller region studied by parallel beam synchrotron tomography revealing that the large 3D structures are formed by several interconnecting particles of different aluminide types (shown in different colours) – voxel size = (0.3 µm)³. c) 3D distribution of Ni (blue) and Cu (yellow) revealed using K-edge substraction with a focused synchrotron beam – voxel size = (24 nm)³.

The capability of alloys to withstand external thermo-mechanical loads is determined by the mechanical and physical properties of the microstructural constituents, their thermal/mechanical stability and their geometrical arrangement. All these parameters may vary during production and service and, therefore, physical aspects such as nucleation/growth/dissolution of phases, diffusion controlled morphological changes and bonding of interfaces must be considered. Furthermore, under the effect of external loads, the microstructural features determine the stress partition between the phases, stress localization and, eventually, damage nucleation and evolution. New critical insights can be gained nowadays owing to the advance of modern characterization methods that allow observing the evolution of the microstructure in situ and/or three-dimensionally, which is crucial for materials with complex microstructures. Specifically, for the companies participating in this project (voestalpine Stahl, Kolbenschmidt GmbH) the relationships between the 3D microstructure and the thermo-mechanical behaviour of their products is of immediate importance for quality assurance and optimization of the production processes.

The activities in this project require the combination of state of the art ex-situ and in-situ 3D imaging methods to reveal the internal architecture of the alloys and the damage formation/propagation together with in-situ bulk diffraction methods to follow the formation and evolution of microstructural constituents as well as their load-carrying capability and deformation mechanisms under different thermo-mechanical loading conditions. Furthermore, physical models based on the experimental observations will be implemented into simulation tools (MatCalc) developed by the scientific partners to predict the flow behaviour of continuously cast steel slabs.