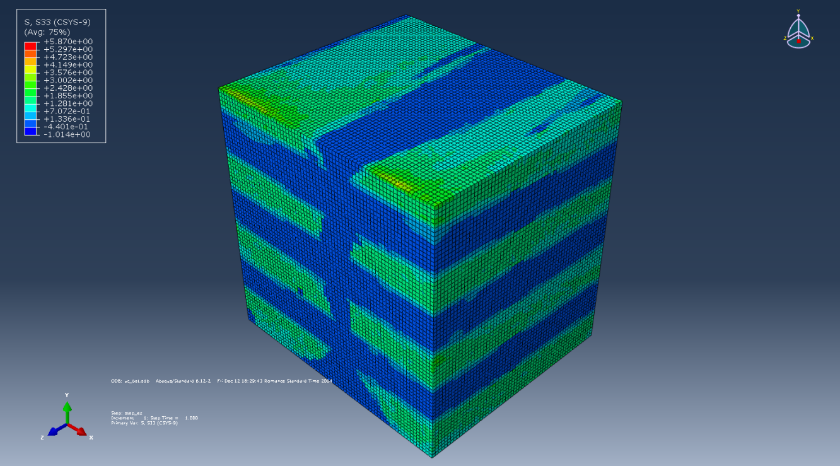

The developed optimized models allow for generating a detailed understanding about the effect of production flaws, such as voids or a deviation in yarn geometry or shape, on the mechanical behavior of the composite structures.

Simulation of specified test scenarios

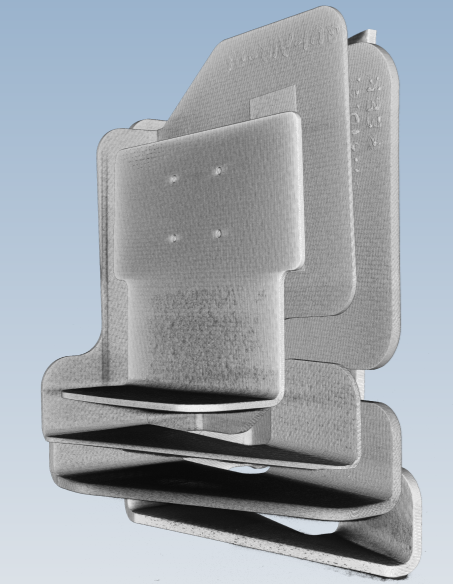

2D and 3D X-ray imaging techniques have been applied, optimized and evaluated on the end user’s samples. The studies focused on investigating dual and multi-energy techniques, as well as artifact removal.

Development and optimization of CFRP models

The studies were based on quantitative data analysis of the real inner structures of composite components, taking into account production flaws. The scanned CT images were further processed and defects were quantified in order to enable CFRP modelling based on the CT input data. In addition, a focus was put on the creation of a progressive damage model for the simulation of CFRPs as well as on the evaluation of the developed models.