QUICOM (Quantitative Inspection of Complex Composite Aeronautic Parts Using Advanced X-ray Techniques) is a Level 1 project funded by the Seventh Framework Programme, which aimed at taking the next big step in the characterization, simulation and modelling of aeronautic components.

The knowledge and understanding related to the defects of CFRP parts are key factors for the application of a damage tolerance approach, and for increasing the safety of composite structures.

From the beginning of the project, the development of QUICOM techniques remained closely aligned to the industrial requirements and guidelines, in order to effectively correspond to end-users needs.

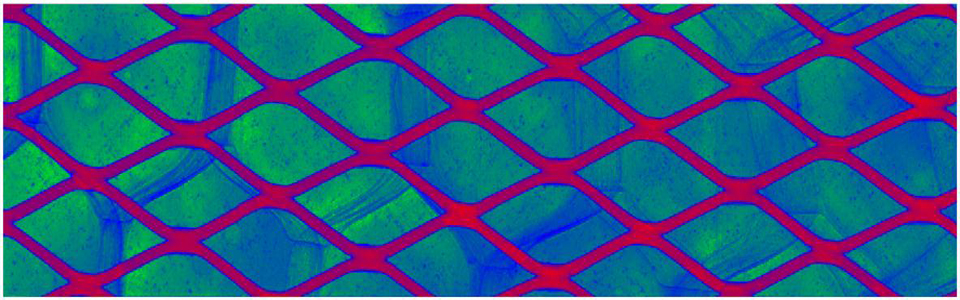

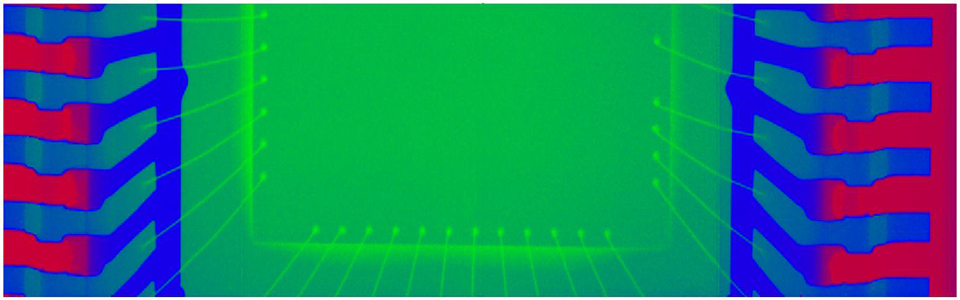

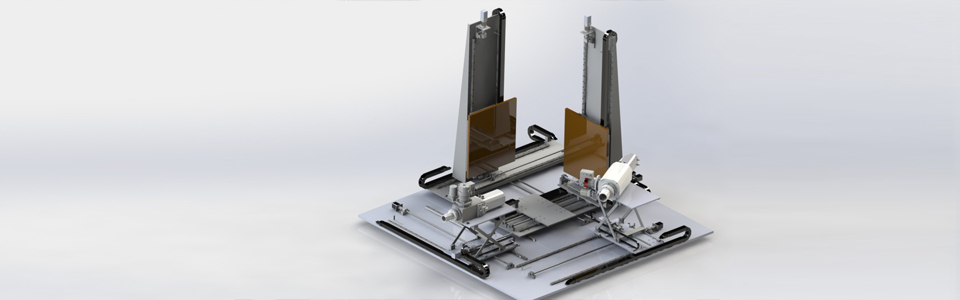

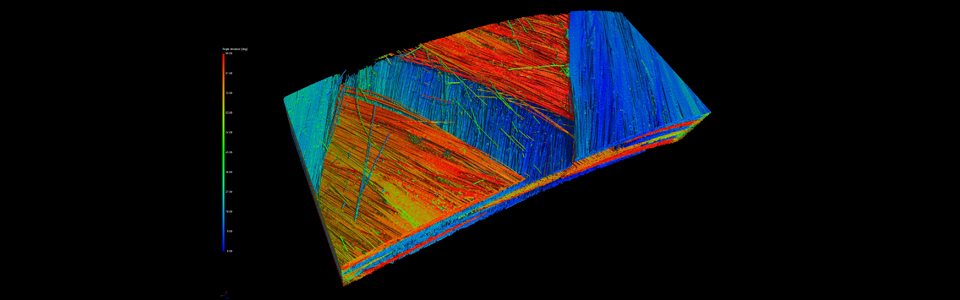

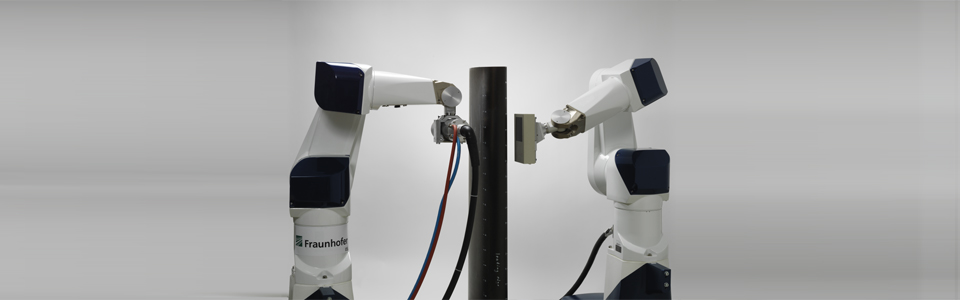

The progress beyond the state of the art focused on the extensive use of X-ray computed tomography (XCT) techniques to detect defects in small high volume parts, composite metallic parts, as well as complex and large composite structures.

The QUICOM technology platform assures thorough inspections at high levels of detail, and hence allows for reducing the design, production and rework costs, due to an enhanced understanding of the real inner 3D structures. The availability of such an inspection can lead to higher structural efficiency and higher performance compared to recent state-of-the-art.

Scanning Protocols and XCT Techniques |

Simulation and modeling |

Software Analysis |

|

|

|

|

|

|

|

|